Page 1 of 3

Question on proper use of carb heat

Posted: Sun Nov 30, 2008 6:27 pm

by Paul-WI

With winter approaching, I have a question on the "proper" use of carb heat. What I "used" to do was pull the carb heat about every 15 minutes and run it that way for a couple of minutes and then push it back in. This did not seem correct. What I am doing now is when I level off at whatever cruise altitude I decide on, I set the throttle where i want it, apply carb heat until the carb temp gauge shows in the green arc, and then adjust the mixture. Somehow this just feels right to me. I have experienced carb ice once and don't wish to do so again. So, is this the proper application of carb heat? I am sure I will receive a number of different correct opinions on this subject

.

Also, as I am approaching another annual inspections and am looking for ways to spend my money, I am wondering - how important is an accurate tach? Mine is off about 150-200 rpm on the high end (tach reads lower than indicated). I know what power settings work for me as far as slow flight, approach to landing etc. Is it really important to have it rebuilt or replaced so that it reads more accurate or is this something I can live with?

Paul

Re: Question on proper use of carb heat

Posted: Sun Nov 30, 2008 9:14 pm

by voorheesh

Carb ice happens when there is moisture content in air within an approx outside air temp range of 30 degF-70degF. The approx drop in temp through the venturi of a carb is 40-50deg. High moisture content (relative humidity) and OATbetween about 50 deg-65deg is where you are most likely to get carb ice. When operating in those conditions, I select full carb heat shortly after start and use during taxi. I start the run up with carb heat closed and open it for about 30 seconds and then close again looking for noticeable drop in rpm followed by a rise back up to run up setting after closing. The above procedure tells me I do not have carb ice prior to takeoff. I use full power for takeoff/climb and note any loss of rpm or roughness. You can get carb ice at any power setting. If I notice a drop in rpm or roughness, I apply full carb heat and hope it clears up. Sometimes it will get rougher before it goes away. Once it smooths out, I close carb heat and/or use partial to full carb heat whatever it takes to stop the ice. During cruise, I set a power setting and tighten throttle friction. If there is any roughness/ loss rpm proceed as in climb procedure. Sometimes you may need to operate with full/partial carb heat. During approach and landing in carb ice condition, I use full carb heat. Thats my SOP and I'm sure there are others.

Re: Question on proper use of carb heat

Posted: Mon Dec 01, 2008 1:42 am

by N2865C

voorheesh wrote:Sometimes it will get rougher before it goes away. Once it smooths out, I close carb heat and/or use partial to full carb heat whatever it takes to stop the ice. During cruise, I set a power setting and tighten throttle friction. If there is any roughness/ loss rpm proceed as in climb procedure. Sometimes you may need to operate with full/partial carb heat. During approach and landing in carb ice condition, I use full carb heat. Thats my SOP and I'm sure there are others.

What I was taught and my operating procedure..... I don't use partial carb heat... You can end up with just enough heat to melt the ice in the top part of the carb, only to have the melted slush freeze up further down the line leaving you in a worse situation. I always pull the carb heat to full. I have had carb ice a couple of time in cruise evidenced by a drop in RPM. It certainly got my attention, but was no big deal after application of carb heat and a couple of spurts and coughs (the airplane, not me

)

Re: Question on proper use of carb heat

Posted: Mon Dec 01, 2008 1:52 am

by Robert Eilers

Paul,

Equipped with a carb heat gauge - sounds to me like your technique is correct.

Re: Question on proper use of carb heat

Posted: Mon Dec 01, 2008 1:58 am

by voorheesh

I don't have any argument with using full carb heat when carb ice conditions are present. That is the best prevention measure. It cuts back on power and may require leaning but if you suspect carb ice, full carb heat is best. I have experienced the use of partial carb heat and lean mixture like the guy in the first post described and it seemed to prevent ice during cruise. If you believe you are in carb ice conditions, applying heat periodically is not a bad idea. If the rpm drops and returns once you close the carb heat, that seems to me to verify you do not have carb ice. The main things I have been taught are you can get it while idling on the ground, climbing at full power, and everything in between.

Re: Question on proper use of carb heat

Posted: Mon Dec 01, 2008 2:34 am

by GAHorn

Well..... here goes....

I avoid taxiing with carb heat applied because that by-passes the air filter, and it is while taxiing on the ground that your engine is most subjected to dirty air. Therefore, during the run-up, after magneto check at 1700 rpm, I pull carb heat ...observe a drop in rpm, and leave the carb heat applied sufficiently long to determine if carb ice has formed during taxi (about 15 seconds) and then remove carb heat. (Carb heat , once applied, will result in a drop in rpm due to heat/overly-rich mixture, and...if ice was present.... will then subsequently indicate an INCREASE in rpm as the ice is removed... and will result in NO increase if no ice was present.) This test warms the carburetor and insures 1) the carb heat works and 2) there is no ice prior to take-off.

Carb heat is then removed for takeoff.

T.O. power is then set (full throttle) and the rpm is noted (2250-2350 is typical) and takeoff is accomplished. As 85-95 mph is achieved (climb speed) I again note the indicated rpm (usually about 2300-2350 with my engine/prop). I leave the power set until cruise altitude is acheived. If ANY rpm loss occurs during climb I check 1) throttle is still FULL and 2) pull carb heat to determine no ice is present (a drop followed by an increase as the ice is melted away) and 3) I then lean to achieve maximum rpm for climb. (This last is necessary only above 5,000' normally.)

Reaching cruise altitude, I let the airspeed build until normal cruise speed is achieved (about 110-115 mph/ IAS in my airplane but yours may be different) and then I apply carb-heat again t o insure I am beginning my cruise with no carb ice. (Carb heat is applied and t he normal drop is noted. After about 15-20 seconds with no other indications, such as a subsequent increase in rpm, I remove carb heat.) I note the rpm. I lean for max rpm. I again note the rpm and adjust throttle to achieve 2450 for cruise.

For the rest of the flight I check rpm to insure that 2450 remains. If any reduction occurs, the cause MAY be carb ice, so I apply carb heat and observe the engine's reaction. (Normal is a reduction due to the application of carb heat, with no further increase or any detrimental missing, coughing, etc.) then I remove carb heat and observe that original cruise power setting is still indicated (2450.)

You see, carb ice will reduce the diameter of the carburetor throat and result in a reduction of power/rpm. So if you note the rpm and see no further reduction, there is no indication of carb ice. If you pull carb heat ON...you will see a reduction due to the overly-rich mixture created by the hot air, as well as a reduction due to the loss of manifold pressure caused by the re-routeing of incoming air in the intake. If carb ice is present , the hot air will melt the ice and a subsequent increase in rpm will occur as the result of the removal of the ice. If NO ice is present, only the initial reduciton will occur and no subsequent rpm change will occur. (Therefore, simply remove the carb heat and continue the flight.)

Before descent, (and before power reduction), apply full carb heat and observe the engine's reaction. It should show a drop....with no subsequent increase. After the carb heat is removed (because no carb ice indication occurred) then remove carb heat, ...then reduce power for the descent.

Here's the important point to remember: Anytime power is SET.... then NOTE that power setting (RPM) and if anytime a subsequent reduction of RPM is observed... SUSPECT CARB ICE. Pull FULL carb heat and watch the tachometer. A reduction in RPM is NORMAL. A reduction followed by an increase is an indication of carb ice.

When the carb ice is melted away, then remove carb heat. Simple, heh? (Whenever carb heat is required, apply only FULL carb heat. Partial carb heat can only be utilized if additonal instrumentation is available such as a calibrated carb-air-temp gauge is available. Unless you have such instrumentation, use FULL CARB HEAT ONLY until all indications of carb ice removal (return of rpm) is achieved. It is only a RARE situation that continuous carb heat is necessary. I seriously doubt if anyone of us actually finds ourselves in that situation. I know that some folks will tell stories where that condition applied to them, but I have personally never experienced it, and I sincerely doubt such conditions actually ever occur that some other indication or failure or mismanagement has not also occured.)

Anytime you suspect carb ice (a reduction in RPM has occured since the last time power was set) apply FULL CARB HEAT and watch that tachometer. A DROP is normal. A BIG drop is a sign of carb ice, especially if that engine hesitates....and then recovers with an INCREASE in RPM subsequent to carb-heat application.

I have experienced carb ice only ONE TIME in my 170 with the C-145/O-300 engine. But it is possible under virtually all atmospheric conditions. Visible moisture/humidity is not a reliable indicator of the liklihood of carb ice. WATCH YOUR TACHOMETER for a reduction of RPM from that which was LAST SET.

Keep in mind that when flying is below-freezing conditions it is UNLIKELY that you will experience carb ice, because any moistue in the atmosophere is already frozen and therefore cannot accumulate in your carb. However, carb ice is VERY POSSIBLE in normal temperatures because the moisture can freeze within that chilled carb throat.

Insure that you have NO ICE presently by applying carb heat.... then NOTE your present RPM.... and LOOK for any unexplained reduction in RPM, which may be caused by carb ice.

Re: Question on proper use of carb heat

Posted: Mon Dec 01, 2008 3:44 am

by Bruce Fenstermacher

I have experienced carb ice several times. When you don't know what it is it is unnerving. I've had it several times in what I thought was moisture free air and at temperatures I wasn't particularly thinking of carb ice. I've actually aborted a few flights landing early at the closest airport not realizing what was going on.

I agree with George except for two things. If I get carb ice or suspect I might get carb ice the carb heat goes on full and stays on when I'm at cruise. At cruise I don't need the power, the heat and rich mixture won't hurt anything, and I feel better. Pehaps if George would get carb ice more than once he might feel more like I do.

I also apply full carb heat before and maintain full carb heat during any decent regardless of the atmospheric conditions.

Re: Question on proper use of carb heat

Posted: Mon Dec 01, 2008 4:49 am

by johneeb

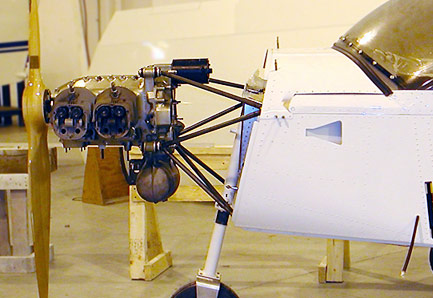

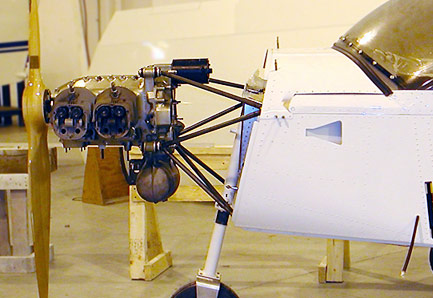

Some excerpts from the 1953 Cessna 170 Owner's Manual.

Click on them to expand for easier reading.

Re: Question on proper use of carb heat

Posted: Mon Dec 01, 2008 3:00 pm

by GAHorn

N9149A wrote:... Pehaps if George would get carb ice more than once he might feel more like I do. I also apply full carb heat before and maintain full carb heat during any decent regardless of the atmospheric conditions.

Perhaps you didn't mean to, but it's insulting to suggest that with 13,000 hours, over half of them in carbureted airplanes, I don't have sufficient "experience" to know how to identify and deal with carburetor ice. I believe that my techniques (which are the same ones taught at the majority of schools) are better suited to dealing with carb ice, and is proven by the reduced number of times I've been surprised by it. (Also I never said I'd had carb ice only "once". I've just not been surprised by it because I've always detected it before it became a problem. Welll.... I take that back.... there was that time when I was a student pilot that it scared the bejeezus out of me. And I've never forgotten to monitor RPM since.) I'm sure you didn't mean it the way I first interpreted it, however.

I believe the practice of flying extensively with carb heat applied is not just overly cautious, but may even be hazardous. Unless a carburetor air temperature gauge is available, operating with carb heat applied over long periods and low power settings is not only less efficient and contributes to increased engine wear... it also may actually contribute to carburetor icing under certain conditions. These comments apply especially to the Owner's Manual comments regarding partial-application. Here's why: Without knowing the actual air temp in the carburetor, a pilot who applies carb heat as a continuously-preventive measure may actually raise air temperatures to the point of allowing moisture-laden air to come to the freezing point. In such case, the already cold air would have been too cold for ice to form except for the fact it was artificially warmed by the carb heat. AVOID use of partial carburetor heat. Use either FULL heat or NO heat, unless you have a CAT gauge.

This is not to suggest that our airplanes should all be equipped with Carb Air Temp (CAT) gauges. I don't believe they are necessary at all in such simple installations. Any ice formed will give adequate warning by producing a reduction of RPM. The problem is usually that of pilots who do not note and monitor RPM settings. (Referring to single-engine, Fixed pitch props. Multi-engined, carbureted, variable-pitch props are more needful of such CAT instrumentation, in my opinion. The early Martin 202/404 and some Convair airliners had them, as examples.)

Manifold pressure gauges are also useful tools in warning of carb ice in that they will demonstrate a loss of MP commensureate with fixed-pitch RPM loss. They will warn of ice with either fixed pitch or variable pitch props if they are properly monitored. I would rather have a MP gauge than a CAT gauge because it will aid in other engine diagnostic functions which CAT gauges will not. A CAT gauge is way down my wish-list.

Application of carb heat enrichens the mixture considerably and, if such practice is what one follows, the engine should be leaned for that condition. Flying along with carb heat applied actually reduces available power because it increases the apparent density-altitude for the engine. The engine thinks it's operating in the desert at high altitude, which causes a loss of horsepower. I am loathe to accept that in my airplane. If I want to fly with reduced power I will accomplish that with the throttle not the carb heat.

From a preventive-maintenance point of view, it's important to inspect the carb heat air passages regularly. The flexible hose (SCAT/SCEET) which introduces air to the heater muffs and to the carburetor air-box can be seen by insects/mud-daublers as wonderful habitat for building nests. Any subsequent application of carb heat can introduce those nests to the carburetor causing engine failure. This has happened in as little as two-days time from the last inspection. (Cessna 172 accident on takeoff from Brenham, two days after annual inspection which replaced the air-box.)

I've found air hoses which had the spiral wire rusted into loose pieces, ready to be consumed by the engine. (That's also why I only use double-walled, high-temp SCEET hose in my carb-heat circuit.) Those hoses are notorious for collecting water in the lower loops areas after airplane and engine washes. A big gulp of water in-flight can be a nerve-wracking experience, so check those hoses after washing down the engine and airplane. (Some folks recommend using an awl to pierce the hose at the lowest point to provide drain holes, but I don't go that far, I just inspect and loosen one end and lower it to drain it, using the opportunity to inspect the interior of the hoses for condition.)

Re: Question on proper use of carb heat

Posted: Mon Dec 01, 2008 6:19 pm

by johneeb

Re: Question on proper use of carb heat

Posted: Mon Dec 01, 2008 6:30 pm

by GAHorn

It depends. Most Lycomings have their carburetors mounted at the base of the oil sump where it is warm, which helps keep the carb warm (especially in down-draft cooling systems like most modern aircraft.)

This is similar to the C-145/O-300 set-up, and therefore both engines have similar frequency-of-occurance of carb ice.

Smaller Continentals have a reputation for increased occurance because those engines have a separate oil-tank, the carb not being mounted directly on the hot oil tank.

Re: Question on proper use of carb heat

Posted: Mon Dec 01, 2008 7:15 pm

by jrenwick

In the climate where I fly most, I've found that carburetor icing is fairly common except in winter. I expect to see it in the first 15-20 minutes of a flight if the OAT is in the 60s or 70s and the humidity is high. Usually carb ice will occur just that once during the flight; after that, maybe the engine is warmed up enough to prevent it from happening again.

This is true in my C90-powered J3 as well in the 170. The J3 is a little more prone to it, I imagine because the cylinders are outside the cowling, and the carburetor doesn't get any of the warm air coming down from them.

I've adopted the philosophy of a British friend of mine who will always opt to land rather than proceed in conditions where carburetor heat must be used continuously, the theory being that once you're using full carb heat, you've no longer got the option of adding it. He owns two C90-powered SIPA 903 aircraft (a two-place wood/fabric French trainer from 1950), and one of them is prone to this. He and I were flying the pair of them together in France a few years ago when he got into some very persistent icing (the one I was flying was fine). We opted to end flying for the day at a nice little town we would not otherwise have seen, and that turned out to be one of the highlights of the trip. Sometimes the best experiences in flying are where you hadn't planned to stop!

Re: Question on proper use of carb heat

Posted: Tue Dec 02, 2008 12:22 am

by GAHorn

BTW, in concurrance with the idea of keeping Ol' Gar's relatives (mud daubers) out of my carb heat circuit, I make extensive use of those plastic pot-scrubbers (trade-named "Tuffy"). I stuff them into my carb-heat inlet ducts, wing-root/cabin-air inlets, cabin-heat cowl-inlets (both of them, the one for the muff-inlet and the one for the fresh-air cabin inlet at the rear engine-baffle), and my oil-sump cooling inlet (beneath the prop). I use "Dixie-cup" wax-paper drinking cups, turned upside-down and stuffed into my exhaust stack tailpipes too (to keep bugs and moisture out of my exhaust and cylinders.)

There is still a vulnerable area we don't much think about: The exit to the air box below the carb-heat butterfly valve. I plan to use a coarse-screen in that location, but have not yet worked out a way to do it legally in any permanent manner. Temporarily a "pot-scrubber" stuffed up there from the lower cowl-exit is the only way to do it for now. Those scrubbers that are stuffed into difficult locations, I tie a long nylon string, such as used on fish trot-lines, to them, in order to easily yank them out during preflight. The opposite, loose-end, I have a "Remove Before Flight" type streamer to dangle out of the cowl so I'll remember to remove it during pre-flight.

The point of all these dauber-defeaters is that even if forgotten, they will do no harm. Meanwhile, they may save my life.

Re: Question on proper use of carb heat

Posted: Tue Dec 02, 2008 3:13 am

by Bruce Fenstermacher

gahorn wrote:Perhaps you didn't mean to, but it's insulting to suggest that with 13,000 hours, over half of them in carbureted airplanes, I don't have sufficient "experience" to know how to identify and deal with carburetor ice. I believe that my techniques (which are the same ones taught at the majority of schools) are better suited to dealing with carb ice, and is proven by the reduced number of times I've been surprised by it. (Also I never said I'd had carb ice only "once". I've just not been surprised by it because I've always detected it before it became a problem. Welll.... I take that back.... there was that time when I was a student pilot that it scared the bejeezus out of me. And I've never forgotten to monitor RPM since.) I'm sure you didn't mean it the way I first interpreted it, however.

I'm sorry George I did not mean to insult you. I typed that without thought having just read your post which included the following:

gahorn wrote:I have experienced carb ice only ONE TIME in my 170 with the C-145/O-300 engine.

I do remember thinking how strange that you had only experienced carb ice once. But then you do live in Texas. Of course I should have thought that through a bit more and realized with your experiance you would have had to have more carb ice than once, even in Texas.

Re: Question on proper use of carb heat

Posted: Tue Dec 02, 2008 3:31 am

by Roesbery

Pretty well been covered but my 2 cents: Been 30 years or so since I flew a 0300 170, but well remember adding carb heat in early clime out one time and almost killed the engine due to overly rich mix. Will never do that again. And yes it did have a greater tendency to get carb ice than the Lycomings I've flown since. That said, Lycomings can and do get carb ice under the right conditions, like the last several months in this area, usually within the first 10-20 minutes sometimes a second time but usually not. And very rare after the engine is completly warmed up. I always check carb heat during run up then leave it off till I'm at a altitude that allows options for a landing other than straight ahead.

.

.