Page 1 of 2

Correct parts are essential

Posted: Tue Jan 23, 2018 5:19 am

by hilltop170

The other day I landed at a friend's ranch strip northwest of Lampassas, TX, at Postoak airstrip, 76TA, for a short visit. Rusty, the owner, videoed my landing and I taxied to the downwind end of the 1700' strip in preparation to leave in an hour or so. Everything was fine when I left the plane but after an hour it was getting late and was time to take off before dark. Rusty took me back to the plane and I couldn't believe it but the left tire was flat! We rounded up some tools and a hi-lift jack was used with a piece of pipe over the jack column and positioned at the wing tie down ring. The wheel was off and taken apart by dark.

Nothing wrong could be found with the tire or inner tube, no cuts, stickers, or nails, except, the valve stem was missing! We looked at the video Rusty had taken from final approach all the way to where I shut down and both tires were inflated the whole time, yet the valve stem was missing and could not be found and the tire was flat an hour later. Go figure!

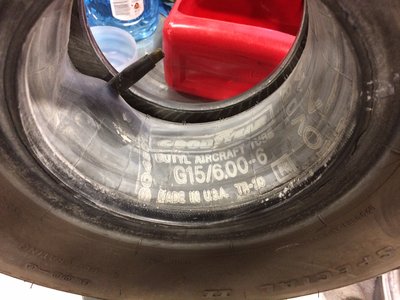

- 6.00-6 on left, G15/6.00-6 on right

- Wrong tube in 6.00-6 tire

Once taken apart, the inner tube revealed it was actually the wrong size tube. Instead of a 6.00-6 tube it was a G15-6.00-6 tube which is for a smaller tire. I don't know how much that had to do with the flat but it was a noticeably smaller tube than the replacement 6.00-6. The wheels, tires, and inner tubes had been installed new in Alaska in 2006 by a reputable shop that did much of the restoration work and they have never been taken apart since then. So I don't know what happened but I'll be talking to the shop about it. Now the right wheel will have to be taken apart to see if it has the correct tube.

Had the tube blown while in the air, I would have landed not knowing it was flat and no telling how that would have turned out. As it was, the failure occurred on the ground while the plane was stopped or moving slowly so no damage occurred.

The right wheel/tire assembly was later removed and taken apart. As was expected, the right tire also had a G15-6.00-6 inner tube installed so it does not look like a random one-time error on the left side. The wrong part had obviously been ordered for both sides and the wrong part was installed on both sides. This was from a well-respected aircraft maintenance shop that should not have made that mistake. Different people order the parts from the people who install the parts so the mistake was made and continued by more than one person.

- G15/6.00-6 valve stem as-found on right wheel at 45° angle

When the right side wheel was removed from the plane, the valve stem was bent over about 45° angle which looked like it was about ready to rip out like the left tire did. The tires were inflated to 26psi as checked a few days before so pressure was not the problem. The valve stems were straight at the last annual in April. The wrong size tube was most likely the problem and could have caused an accident. Luckily no accident happened.

The lesson to be reinforced here, I think, is to ALWAYS be sure you install correct parts and if a substitution has to be made, an approved part is installed.

Re: Correct parts are essential

Posted: Tue Jan 23, 2018 2:46 pm

by MoonlightVFR

I like this posted info.

valuable to the community

This could save lives

regards

Re: Correct parts are essential

Posted: Tue Jan 23, 2018 3:27 pm

by wingnut

Richard,

I'm going to fess up here.............remember when I bought you a new set of Cleveland wheels and brakes, after Darryl accidentally splashed some paint stripper on your relatively new Cleveland wheels and brakes??? Well, I didn't replace the tires or tubes (they were only a year old), but I did obviously have the tire/tube off the old wheels and installed them onto the new wheels. I/we should have caught it then

We may not have even removed the tubes from the tires to identify the part number, but that's still no excuse; we have a policy to "ASSUME IT'S WRONG" before reassembling anything. We failed on this count. I'll be happy to drop ship the correct tubes to you, or reimburse your expense.

EDIT #1- Just checking to see what the G15/600-6 fits. Apparently there is more to the part number. Spruce shows the G15/600-6 T20(2) fits a 6.00-6 tire, but there are other G15/600-6***** that do not; they are smaller.

http://www.aircraftspruce.com/catalog/l ... tire67.php

EDIT #2- Interesting........So far, every source I have found says the G15/600-6 tube is eligible for both the standard 6.00-6 and the 15x6.00-6 tires.

Re: Correct parts are essential

Posted: Tue Jan 23, 2018 4:40 pm

by GAHorn

This situation is actually not un-common. The reason is often due to the fact that order-clerks and shipping-clerks are not ordinarily held responsible for errors made during selection. The installer/mechanic/repairman tells the parts-window-clerk he needs a new tube for a C-170...the clerk askes what size,...the repairman says 6:00-6, and the clerk looks at the chart below... and does not know the difference between a 15/6:00-6 and a 6:00-6...because the charts do not distinguish them well. Start at the upper/left of the chart and work your way down to a tube that is described as 6:00-6 and see what first pops-into view:

Imagine you are disassembling a wheel for some reason other than a leak....and find a tube marked G15/6:00-6 inside... Would YOU have thought more about it before Richard's post?

Let me ask another question...simply for the purpose of illustrating how insidious these types of errors can be: How can you distinguish between an automotive schrader-valve (valve-core) and an aircraft valve? (If you are a professional A&P, and you know the answer .... allow our other Members to post before revealing the answer.)

There will be a follow up on this question later.

Re: Correct parts are essential

Posted: Tue Jan 23, 2018 5:22 pm

by wingnut

George,

After a bit of research, I find the G15/600-6 tube to be the correct tube for the 6.00-6 tire, but not the only correct tube.

Re: Correct parts are essential

Posted: Tue Jan 23, 2018 5:43 pm

by GAHorn

Thank you, Del. I was assembling some further info on this matter... I feel it's important to mention to Members that during PRE-FLIGHT inspection ...one of the important items to check is VALVE-STEM position. Richard's photo illustrates a tire/tube which has slipped relative to each other...likely due to underinflation at some point.

Upon landing a tire is met with the problem of "spin-up" when it contacts the runway surface. This can cause the tire to slip on the wheel/rim and the inner tube is held captive/in-position by the valve-stem passing thru the wheel. This is what makes that valve stem appear "slanted" and can lead to a destroyed tube.

In fact, when installing a tube within a tire, it is usually recommended to use talc to allow a certain degree of slippage between the tire and tube for fitment purposes. (DON'T BREATHE THAT STUFF!) This can actually add to the propensity of the tire to slip seperately from the tube.

The thing we should all be doing... but is not very common... is to MARK the tire and wheel so that slippage can be detected. (Navy requirements are:Tire slippage marks are required on all tube-type aircraft tires inflated to less than 150 psi and on all helicopter tube-type tires.) Any slippage should call for inspection/correction. While the traditional method is to paint a 1" wide stripe which matches the tire sidewall to the wheel-rim... at the very least owners should note that the tire balance point (red dot) should be installed and remain at the valve stem location. During pre-flights... roll the airplane until the tire and valve can be viewed (if wheel-pants/fairings are installed) and look for slippage.

Re: Correct parts are essential

Posted: Wed Jan 24, 2018 1:32 am

by hilltop170

Del-

I appreciate your post, thank you. But no, you do not owe me anything, I had forgot you had replaced the wheels. The tubes placed side-by-side were the same difference in size as the tires, about 30% difference. The straight 6.00-6 tube was significantly larger and seemed thicker although I did not measure it. The G15/6.00-6 tube was much smaller and more flimsy. It no doubt worked for 12 years but I feel much better knowing a full-size 6.00-6 tube is in both tires. Talc was used in both tires.

To add to the tube post, the Goodyear Flight Special II tires are wearing like iron, only .020" wear difference between the inside and outside of the tread after 397 hours. Both tires were reversed to even out the tread wear and the bearings were cleaned and re-greased, so 500 hours more flying before that needs to be done again!

Re: Correct parts are essential

Posted: Wed Jan 24, 2018 6:12 am

by W.J.Langholz

To help Dick out ....Postoak Ident is 76TA

Re: Correct parts are essential

Posted: Wed Jan 24, 2018 4:13 pm

by W.J.Langholz

W.J.Langholz wrote:To help Dick out ....Postoak Ident is 76TA

Richard Pulley has informed me that Dick (Lemmon) has past away several years now, I was unaware. The above post was in reference to him. One of my memories of Dick was that he would always chime in when we would use Idents instead of City names or vice versa....................

So Dick send us a note and let us know what the ident is for heaven

Tailwinds

W.

Re: Correct parts are essential

Posted: Sat Jan 27, 2018 4:21 am

by nippaero

This is good information. I learn something new every time I visit the forum. I will no doubt be keeping a closer eye on my tires during pre flight now.

a hi-lift jack was used with a piece of pipe over the jack column and positioned at the wing tie down ring.

On the other hand, I'm shocked no-one made a comment about this. I thought that was pretty ingenuitive.

Re: Correct parts are essential

Posted: Sat Jan 27, 2018 4:29 am

by hilltop170

Thanks, nip-

I thought up the hi-lift jack method when I had a Super Cub and no good way to change-out tires and skis in a small hangar. I normally use a piece of 3” electrical conduit over the jack column at the tiedown ring. Use the longest pipe possible to increase stability. A small piece of wood between the lift strut and conduit protects the strut paint.

Re: Correct parts are essential

Posted: Sat Jan 27, 2018 4:34 am

by hilltop170

gahorn wrote:

Let me ask another question...simply for the purpose of illustrating how insidious these types of errors can be: How can you distinguish between an automotive schrader-valve (valve-core) and an aircraft valve? (If you are a professional A&P, and you know the answer .... allow our other Members to post before revealing the answer.)

There will be a follow up on this question later.

OK George, we have held our breath long enough, nobody knows.

Re: Correct parts are essential

Posted: Sun Jan 28, 2018 12:32 am

by lowNslow

I think it has to do with the pressure limit, 200psi for cars, 400psi for aircraft comes to mind. The ones for aircraft struts are much higher.

Re: Correct parts are essential

Posted: Tue Jan 30, 2018 6:15 pm

by GAHorn

hilltop170 wrote:gahorn wrote:

Let me ask another question...simply for the purpose of illustrating how insidious these types of errors can be: How can you distinguish between an automotive schrader-valve (valve-core) and an aircraft valve? (If you are a professional A&P, and you know the answer .... allow our other Members to post before revealing the answer.)

There will be a follow up on this question later.

OK George, we have held our breath long enough, nobody knows.

Re: Correct parts are essential

Posted: Tue Jan 30, 2018 6:46 pm

by GAHorn

Higher quality and pressure design. (Not so important in our tires probably, but for larger aircraft and oleo-struts and actuators it's not uncommon to see 1,000 psi + pressures and some actuators are back-up emergency systems where a loss of pressure could be catastrophic. It's a good trivia-question for light planes.)

The emer/back-up elevator down-strut on a Cheyenne which backs up the SAS on that plane can cost you your life if it fails and it's charged with 2K psi of Nitrogen is one example.