Page 1 of 1

SK70A52-4

Posted: Sat Apr 15, 2017 3:34 am

by c170b53

A potential new member was looking for advice and possible paperwork with regard to the tailwheel fish mouth replacement and the use of fasteners other than 5/32 rivets. I've seen examples of field repairs exhibiting AN3 bolts in lieu of rivets but has anyone encountered paperwork covering this. I know we have in the MX library SL's for the conversion from old to new style SK70A52-4, was wondering if there's anything more.

Re: SK70A52-4

Posted: Sat Apr 15, 2017 12:18 pm

by Bruce Fenstermacher

If we could only document approval for all mods seen in the field. I dare ponder the staff it would take and the size of the forum required.

I'm afraid your going into the vast grey region of acceptable practice where one decides that this thingamabob is structurally equivalent to the thingamajig that is called for but can't be used for reasons such as fitment, installation difficulty or unavailability and you doubt any all knowing authority would call you on it.

And there it is. That last paragraph of brilliant wisdom should seal the deal for this perspective member who dares stand on the fence. Wondering whether to fall to the side of membership or wallow in the vast unknown. Endlessly wondering about with an extra coffee and donut to entice those who've taken the plunge, to babble endlessly about required subject matter, in order to acquire such words of wisdom of the collective, second hand.

Re: SK70A52-4

Posted: Sat Apr 15, 2017 3:23 pm

by c170b53

Thanks Bruce, I thought I came across paperwork covering this before but it eludes me now.

Re: SK70A52-4

Posted: Sat Apr 15, 2017 3:31 pm

by n2582d

Jim,

I too wish I had the perfect answer to entice a potential member to join. I'd put it in the members only section.

A smart-aleck response would be to not to just use 5/32" rivets because the majority of the rivets in the conversion are 3/16" rivets.

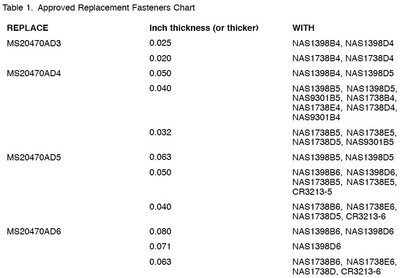

Most self-respecting mechanics would be embarrassed to install blind rivets or bolts in a place that called for driven rivets. His AME should look to Cessna's Structural Repair Manual and AC 43.13-1B for guidance. AC 43-13-1B, fig 4-18 gives an example of a stringer splice using bolts and rivets. Tables 4-9 through 4-11 show how many AN3 bolts or rivets are required for splices. I can't find anything in AC43.13-1B that allows carte blanche substitution of rivets with AN3 bolts. Cessna's Single Engine Structural Manual has a section entitled "Substitution of Rivets". Here are some applicable sections from there:

- Click to Enlarge

- Click to Enlarge

Back in the '80's I was flying and maintaining an L-19 for the Sheriff's department in the desert east of LA. Based out of Thermal airport I ran across some interesting characters. One guy in particular seemed to be Gomer Pyle gone bad, trying to make some quick money flying illicit drugs across the border. He had a clapped-out Beech 18 with a 55 gallon drum aux. tank inside "because these radial engines use a lot of oil". One day he forgot to lock the tailwheel on landing and ended up in the tumbleweeds with a bent tail. To repair the damaged tail he used screws and nuts from the local hardware store. Probably not an FAA-approved repair.

Re: SK70A52-4

Posted: Sat Apr 15, 2017 3:58 pm

by c170b53

Couldn't agree more.

I've advised against such a repair as it will forever stand out, devalues the plane, and won't be as strong. I have seen it more than once though on a stroll.

Re: SK70A52-4

Posted: Sat Apr 15, 2017 4:40 pm

by lowNslow

n2582d wrote:Jim,

A smart-aleck response would be to not to just use 5/32" rivets because the majority of the rivets in the conversion are 3/8" rivets.

Did you mean to say 3/16" rivets ? That would be a bear to have to drive 3/8" rivets.

Re: SK70A52-4

Posted: Sat Apr 15, 2017 5:04 pm

by n2582d

Oops. Good catch Karl. Original edited.

Re: SK70A52-4

Posted: Tue Apr 18, 2017 5:52 am

by GAHorn

I'd certainly discourage the use of bolts or machine screws in that application anyway as the tailwheel bracket is a highly-stressed part ...the movement of the bracket is one of the abuses that causes failure...and the use of threaded fasteners would require close-fitting bolts (probably NAS) and all the holes would have to be equalized by reaming or they would not be sharing the load. With that many fasteners it'd be a B*&tch to do.

Besides, Rivets are such a simple and strong method.

Re: SK70A52-4

Posted: Tue Apr 18, 2017 11:47 am

by sfarringer

And, when you start riveting the bracket on, the riveting will cause intergranular corrosion hiding in the stringer reinforcement angles to expand and become obvious...

Yes, it happened to me..., resulting in more fun bucking rivets inside the tailcone. But better to find it and fix it.

Re: SK70A52-4

Posted: Mon Apr 24, 2017 10:20 pm

by Sask170b

Thank You Jim for posting the request for information. I should have looked a little longer at the forum postings before starting another of my own. Now that I'm a member I believe I fell on the right side of the fence.

Re: SK70A52-4

Posted: Tue Apr 25, 2017 4:19 am

by n2582d

Welcome to the Association! Sounds like you are jumping into the deep end of the pool so to speak.

This post talks about replacing stringers back in the tailcone area -- something it sounds like your AME should consider doing.